From planning to field execution, our Construction Advanced team can bring value to every project through fabrication. During preconstruction, we identify specific opportunities for fabrication for the project, enhancing safety, quality and productivity.

Safety, quality and productivity through fabrication

Products

- Underground feeder conduit stub-ups

- Duct banks

- Assembly of ‘long span’ fixture types for office areas

- Fabrication and installation to fixture of pendants, whips and support cables for industrial and garage fixtures

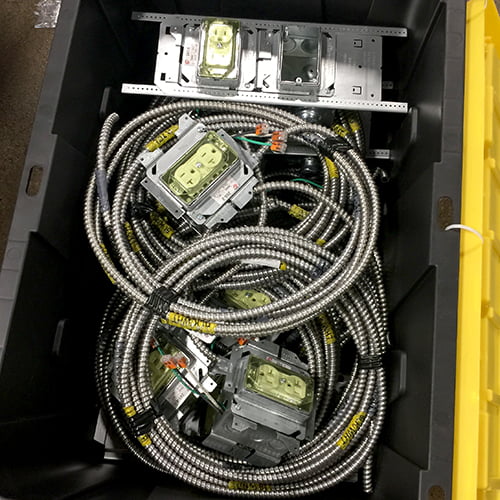

- Fabricated MC cable branch circuiting for lighting

- Pre-cut and terminated MC lengths of 12’, 16’, 20’ and 26’, packaged by fixture type

- Lighting junction boxes with support rod assembly attached and support ‘plate’ for MC or EMT conduit

- Light fixtures palletized by area, excess packaging removed, whips installed, lamps installed, stored off site and shipped as needed

- Pre-built electrical room panels and transformers

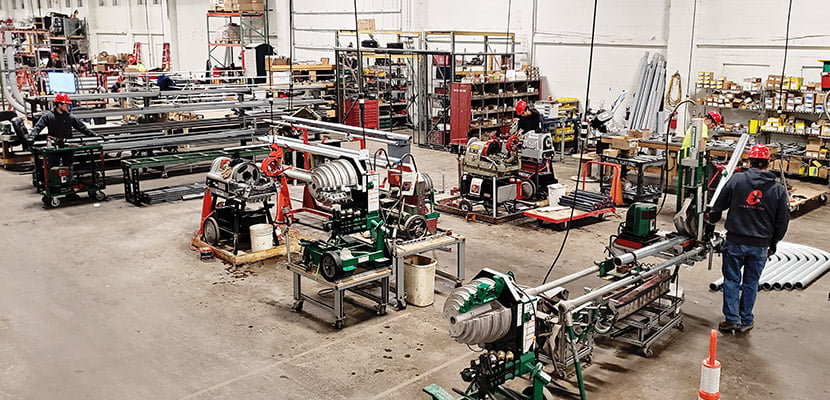

- Pre-bending of all electrical conduit, including feeder conduit in the electrical rooms that will all be pre-bent in our Construction Advanced shop

- Low voltage stub ups for in-wall rough-in

- Fabricated MC-cable in-wall rough-in for boxes and receptacles

- Fabricated strut trapeze supports for conduit racks

- Junction box with flex whip for ceiling devices

At Capital Electric, safety is everyone’s responsibility.

At Capital Electric, safety is everyone’s responsibility.

Construction Advanced allows us to move hours off the job site. Fabrication can dramatically reduce the number of hours spent working in potentially hazardous site conditions. Building a conduit rack in the shop at floor level is much safer and easier than building it up in the air on a congested construction project. Because crews don’t have to work on elevated platforms, they have the right tools, they aren’t working around operating equipment and can work under controlled conditions. This means less exposure to potentially hazardous situations.

Fabrication reduces stress and improves decision making. Construction Advanced reduces stress caused by unexpected problems and time crunches, allowing supervision and craft professionals to maintain their focus on safety.

Products built in a controlled environment with consistent methods have fewer errors. Construction Advanced also allows for forced planning and pre-testing of components before installation.

Construction Advanced products and installation methods allow us to maintain company- and project-wide standards for materials and methods.

Pre-planning delivers both functional and organized layouts. The labeling on the Construction Advanced fabricated items gives future maintenance personnel an advantage when doing any troubleshooting or additions.

Pre-planning delivers both functional and organized layouts. The labeling on the Construction Advanced fabricated items gives future maintenance personnel an advantage when doing any troubleshooting or additions.

Identifying potential coordination problems early allows time to work with other contractors to find the best overall solution before it affects field labor.

Designing and building ahead of time reduces field delays, which is a win for the customer.

The Capital Electric Construction Advanced team uses manufacturing methods to produce individual assemblies, with special tooling and increased production goals. Manpower installation time in the field is reduced because a greater part of the work is completed in the prefab shop.

The Capital Electric Construction Advanced team uses manufacturing methods to produce individual assemblies, with special tooling and increased production goals. Manpower installation time in the field is reduced because a greater part of the work is completed in the prefab shop.

Accurate design and documentation help us do it right the first time in a safe, climate-controlled area with tools and material at hand. This reduces distractions and work stoppage and increases efficiency.

Construction Advanced allows our field leadership to focus on running projects more efficiently and reduces the number of people on site. Project supervisors can focus more attention on a smaller number of on-site workers, making them even more effective. Fewer field personnel equals more control.

Fabrication assemblies can be built and stored ahead of schedule. Because much of the work takes place in a controlled environment, there are no weather-related delays to contend with. This all equates to labor savings.

More trash is confined to the Construction Advanced shop area where it is easily recycled. Work stations are permanent and don’t have to be set up each day.

We constantly ask our crews for their ideas. Do you have a new design for a universal support bracket to be built by the Construction Advanced Team? We will bring your idea to life.